The enzymatic complex is a mix of different enzymes that have been collected from a “mutual aggression” of different species of fungi. With industrial scale production capabilities.

The fractions of interest are defined as those that provide degradation, activity with changes in pH, increase in kinetics, or other.

What makes us different

Key aspects

Reaction begins immediately when the sample comes into contact with the enzymatic mix

No solvent-based pre-treatment needed

Without pH requirements

Enzymes that can act on plastics that are more resistant to biological cleavage, without crystallinity constraints

Industrial scale capability

No need to pre-wash to remove contaminants organic and in-organic compounds in the plastics

No need for hydrolysis or other solvent based pre-treatments

Direct application of nano-encapsulated enzyme mix on the plastics

Proprietary innovative bio de-polymerization

Entzimatiko has developed an enzymatic based De-polymerization with no solvent-based pre-treatment needed.

Enzymes & plastics

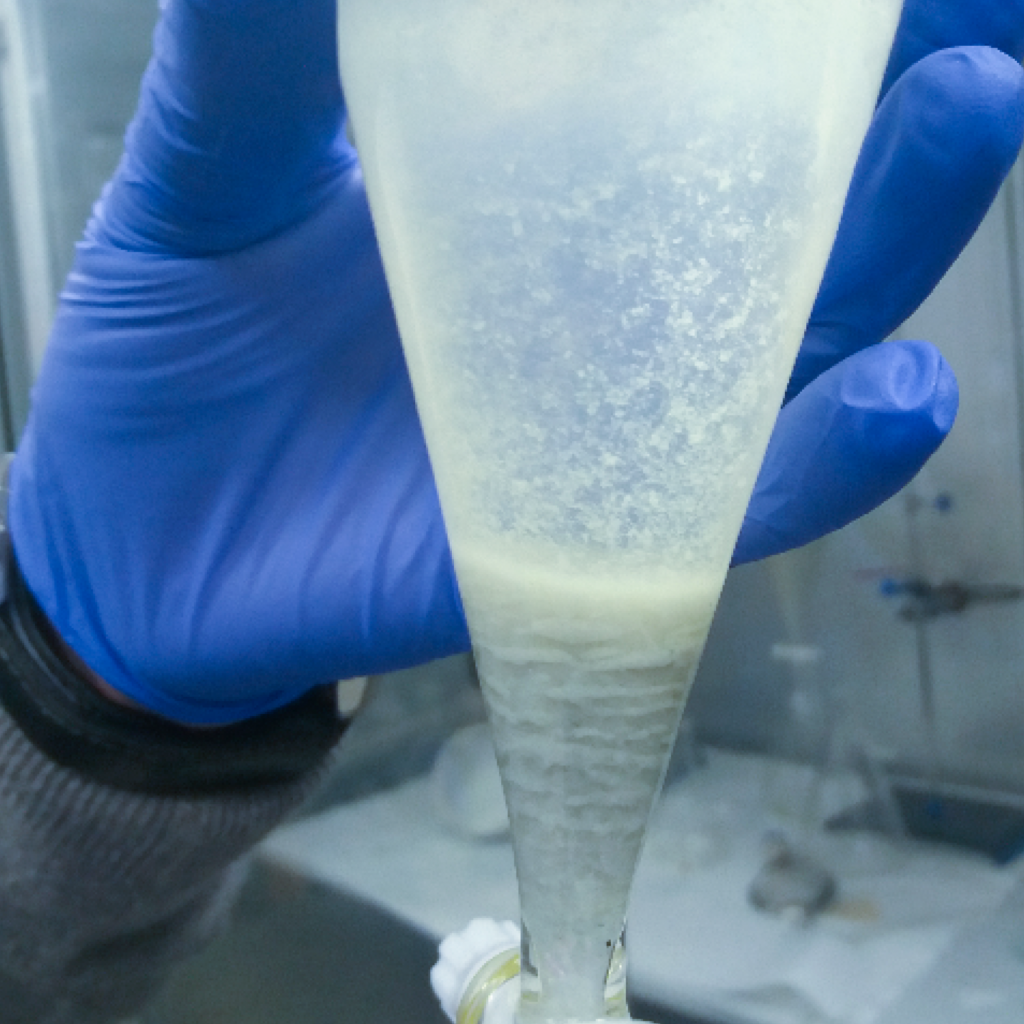

Decanter

Centrifuge

Monomers Oligomers Compounds

Surface lysis

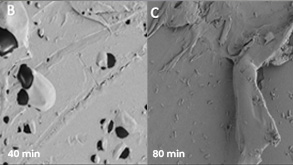

Polymers are very recalcitrant compounds in order to avoid immediate degradation in a natural environment. Therefore, they have a high surface hydrophobicity. The mix allows the formation of substrate binding pockets and the adhesion of enzymes to the polymer surface.

This surface lysis of the polymer allows the release of certain molecules, increasing the efficiency of the biodegradation of the plastics.

Advanced bio-polymers

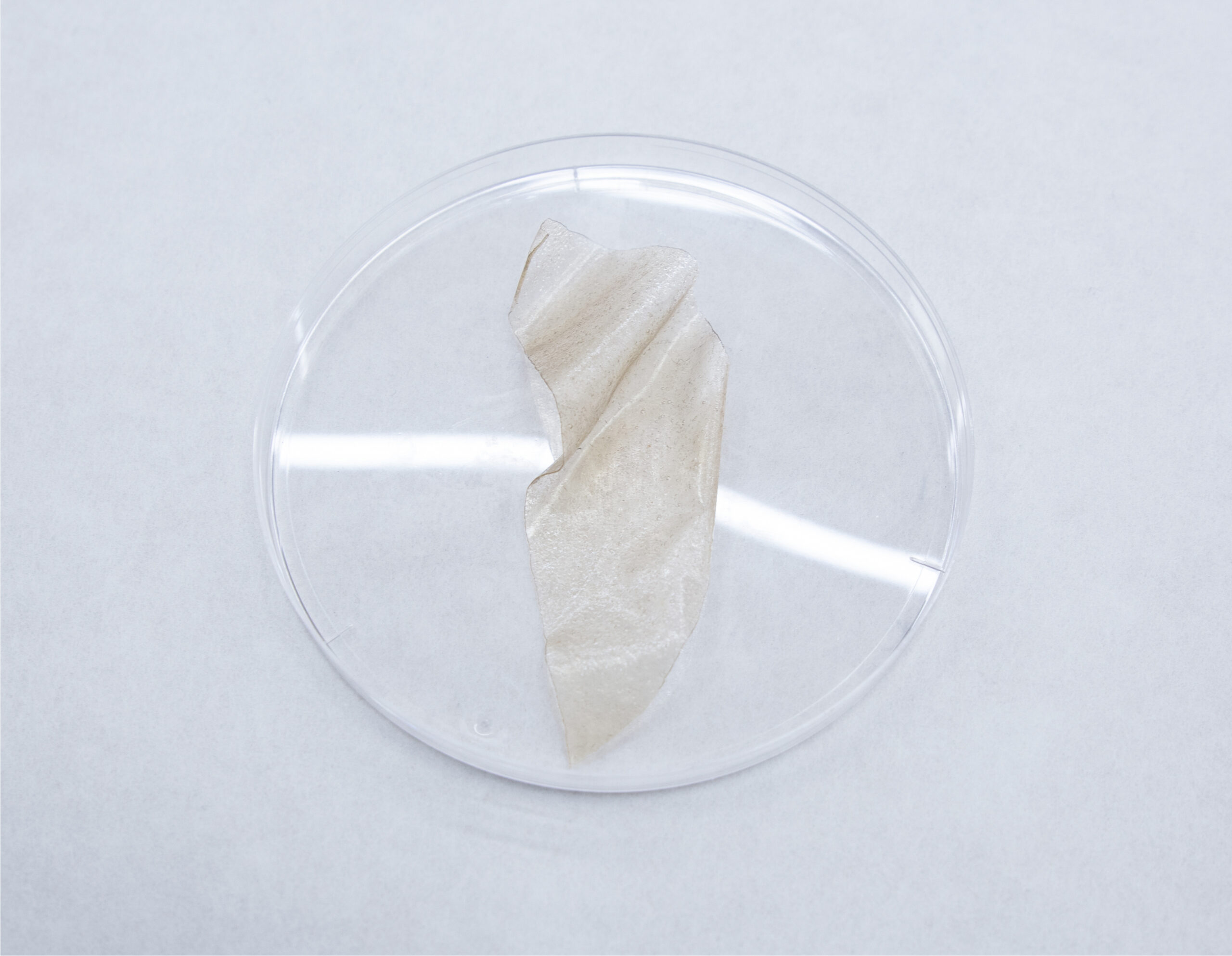

As we continue to innovate with disruptive technologies, Entzimatiko is currently working on bio-based PLA

We take organic waste or non-food crops as carbon sources to produce PLA.

Polylactic acid, also known as PLA, an environmentally friendly thermoplastic monomer derived from renewable,

biomass resources and organic waste streams.